A Multi-Faceted Technology Platform for Solutions in Manufacturing and Business Operations.

Requirements

Business Need

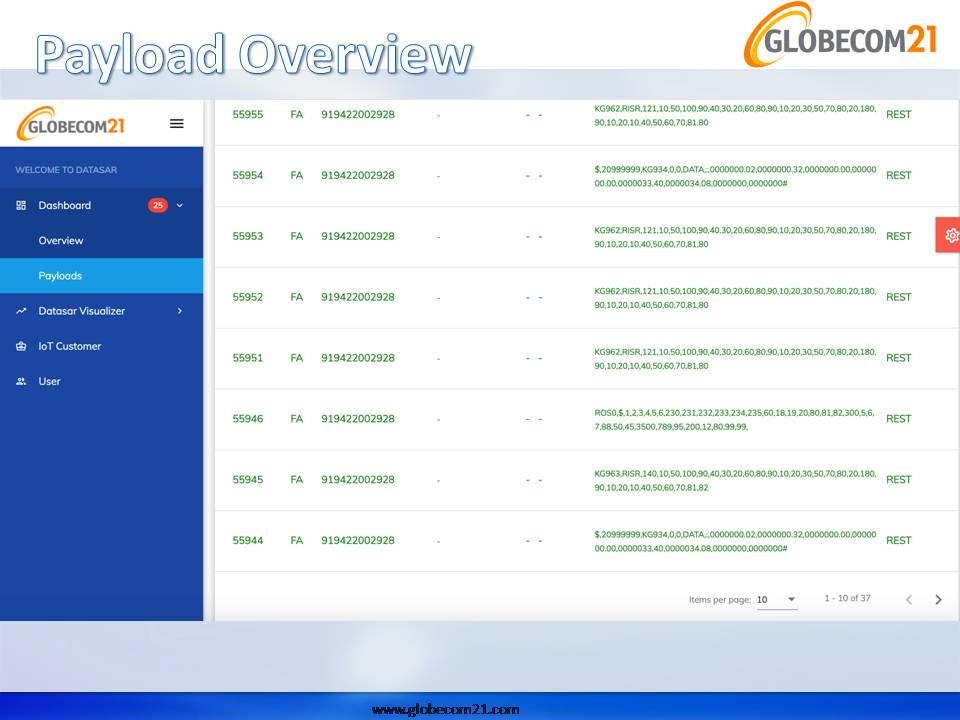

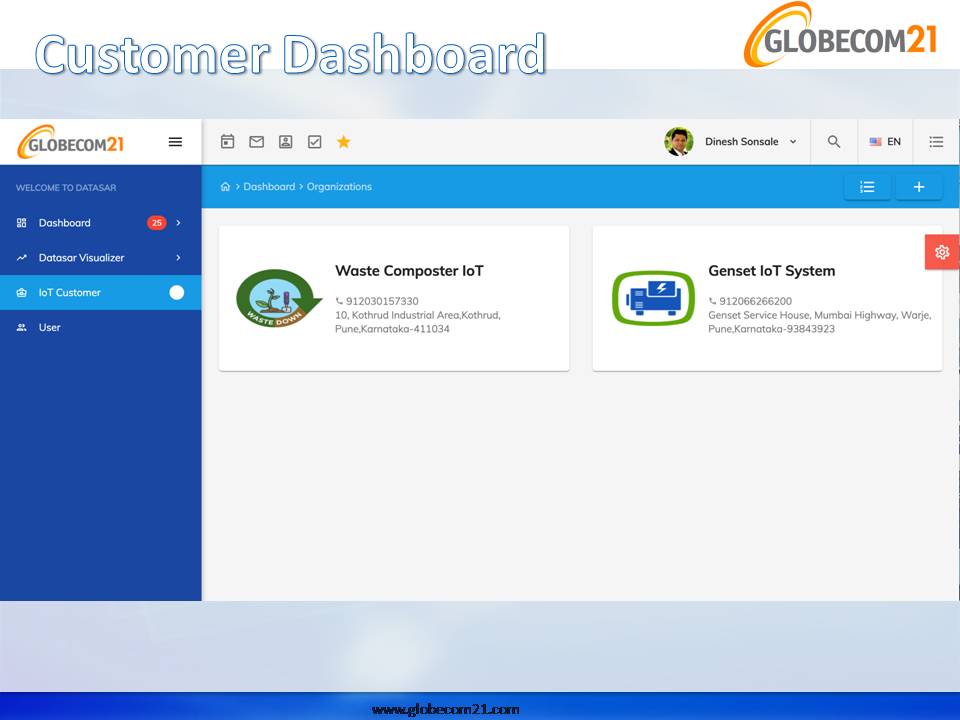

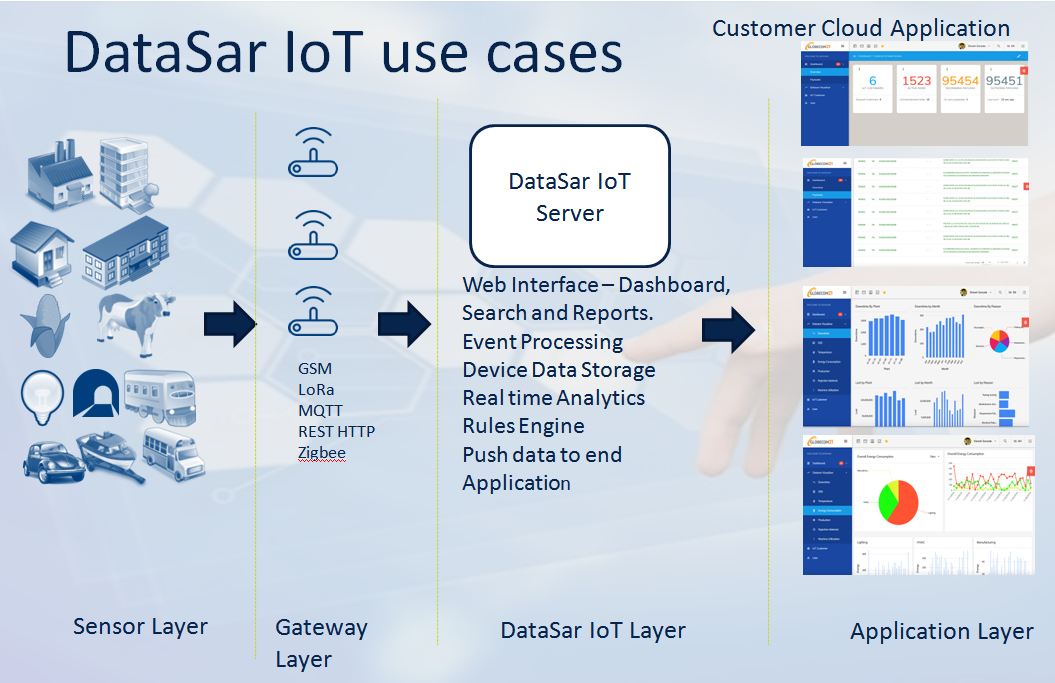

DataSar IoT Platform, enables customers to get (automated, intelligent and highly secure) connectivity from the edge to the cloud in manufacturing, service, maintenance, asset monitoring, supply chain, inventory, and logistics management.

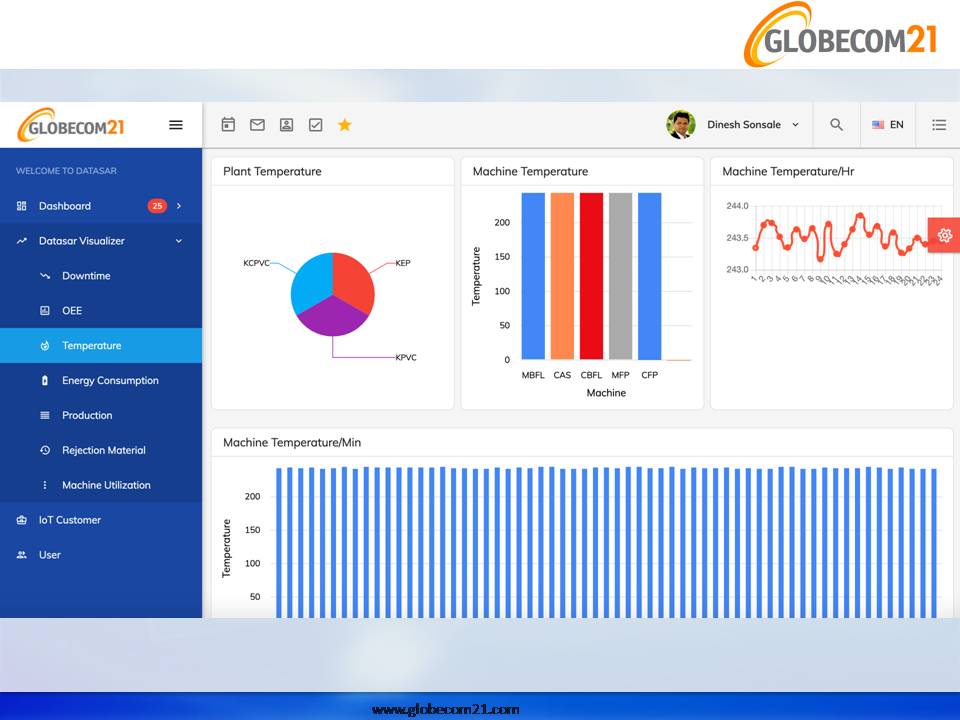

DataSar offer a comprehensive, basic IIoT scheme to connect to your equipment, collect data, begin data/alert/notification workflows, deliver role-based dashboards, and more. DataSar monitors, reports, sends and exchanges data on a collection of interconnected physical device in operations where devices use sensors to measure specific aspects of the world around them, including location, temperature, humidity, light levels, movement, handling, speed of movement and other environmental factors. IoT devices come in many form factors including RFID chips, smart device and mobile sensors.

DataSar platform differentiation is to connects with multiple protocols and hence has ability to connect wide variety of Instruments, Sensors and Industrial automation products. It delivers IIOT solutions inside firewall (Edge and Fog Solutions) as well as on Cloud. Due to its architecture (inside firewall as well as on Cloud solutions) provides more security as compared to pure open platforms like AWS IoT

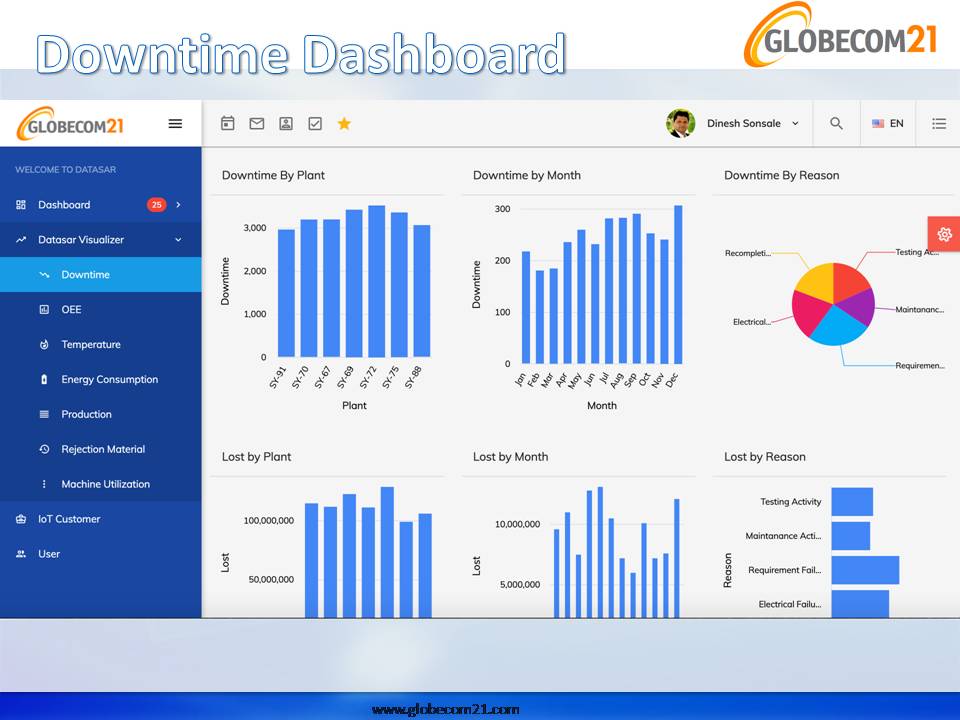

Generating set maintenance is based on time schedule instead of pre-detection of possible failures

Extreme Use Case conditions on field can not be monitored to refute warranty claims

Increased Down time for generating as there is no mechanism for early detection & indications of possible failures

Less efficient operation (possibility of additional DG Sets)

OPEX expenses are difficult to track for end customer ( Diesel Theft ?)

Requirement of dedicated onsite person to ensure Security of remote location DG set

Datasar Demo

Product Features

Monitor

Monitoring vital parameters of asset

Security

Ensure reliability and Security. The data is sent in the encrypted format, which is then transformed and forwarded apps.

Address issue

iCAM hardware and software workflow automatically closes the issue.

Reports

Generate Management Information Reports for OEM and Service Provider

Web Interface

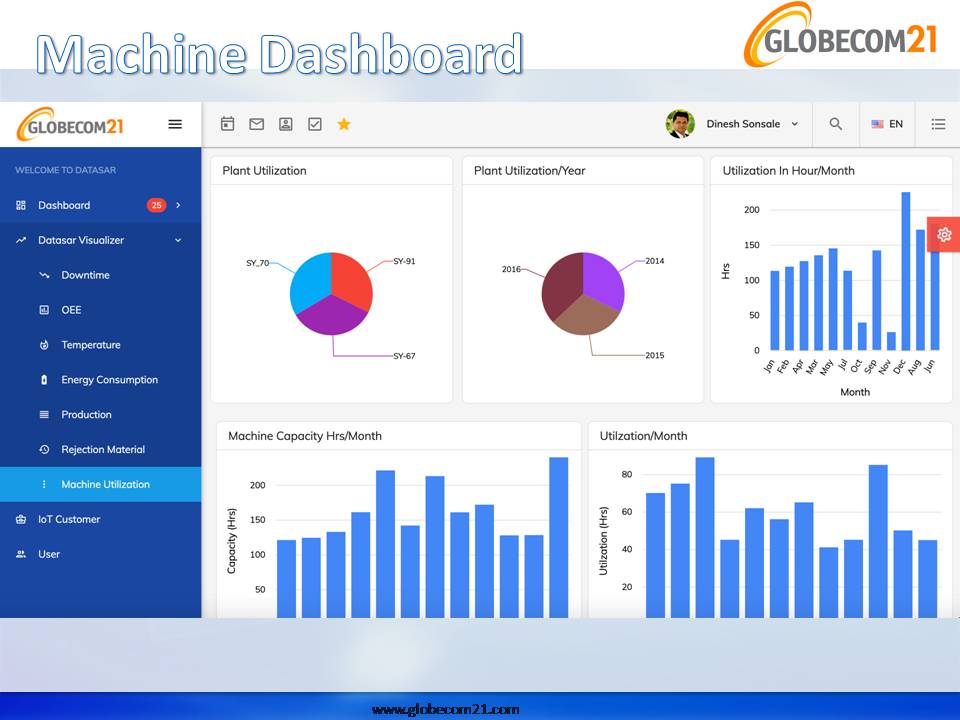

Provide personalized Dashboard, Search and Reports

Raise Alarms

Raise alartm based on prognosis analysis