Industry 4.0

Pre-Built Solutions

Manufacturers are under constant pressure to minimize downtime, improve quality, and respond faster to individual customer requirements, all while lowering costs.

The DataSar Manufacturing Apps are pre-built solutions that can be installed in less than 60 minutes without disrupting production. These apps provide manufacturers with real-time visibility into factory floor operations, from individual dataSar’s to assets to plants to enterprise-wide operations.

The DataSar Manufacturing Apps and building blocks help you improve operational efficiency and workforce productivity across the shop floor by equipping workers with role-based apps that bridge IT and OT, enabling your teams to view, understand, and act on industrial data in real-time. These apps and building blocks are built on the DataSar Industrial IoT platform to accelerate time to value.

Manufacturers face challenges such as defective products, on-time delivery slippage, excessive scrap and rework, unacceptable equipment downtime, and supply chain disruption. As the number of assets and production facilities increases, it becomes more difficult to diagnose and react to these challenges in a timely and scalable manner. Such difficulties can have cascading effects on production schedules and translate to higher production costs, lost profits, missed order fulfillment and reputational damage. Information silos and manual data collection add complexity to making near real-time operational decisions.

It is imperative that its machines operate reliably and that parts and materials are available at every production step, to ensure that products being made meet quality standards. DataSar Manufacturing Insights from Globecom21 leverages AI and machine learning (ML) techniques to provide answers to these challenges, by connecting data from man, machines, method, and materials for situational awareness.

Pointing your domain to Storefront with CNAME records

You can add a CNAME (alias) record to your DNS (Domain Name System) zone file for a domain registered with GoDaddy. CNAME records use a domain prefix, such as IceBlox Storefront point your domain to another domain name, or URL. To add a domain prefix that...

Datasar Platform Milestone Achievement

Today Datasar Platform successfully processed more than 2,00,000 payloads. Datasar is a flagship IoT Platform developed by Kangiten Technologies Pvt. Ltd. we have achieved one of an important milestone and many more to come.

Waste Composter Service Engg App

Waste Composter SIoT Commissioning

Waste Composter SIoT Introduction

Genset SIoT Commissioning

Genset SIoT Customer Mobile App

Genset SIoT Service Ticket Workflow

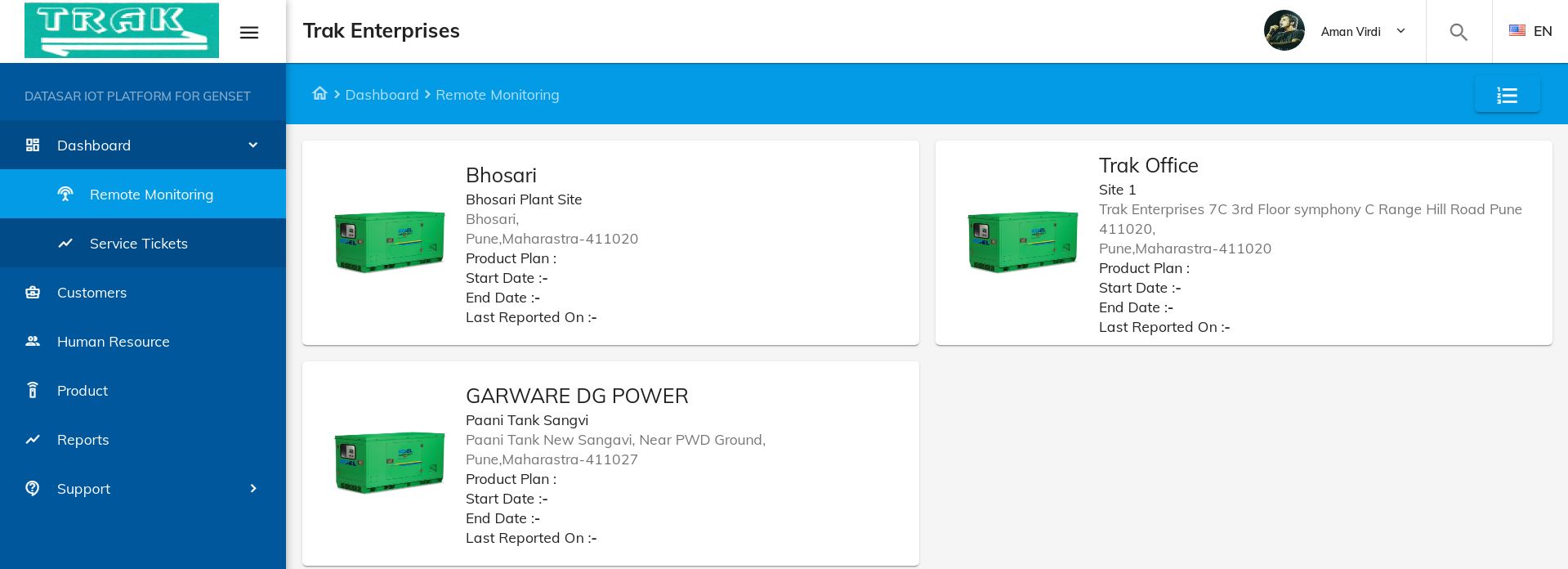

Genset SIoT & RMon Introduction

Industry 4.0

First came steam and the first machines that mechanized some of the work our ancestors did. Next was electricity, the assembly line and the birth of mass production. The third era of industry came about with the advent of computers and the beginnings of...

Pointing your domain to Storefront with CNAME records

You can add a CNAME (alias) record to your DNS (Domain Name System) zone file for a domain registered with GoDaddy. CNAME records use a domain prefix, such as IceBlox Storefront point your domain to another domain name, or URL. To add a domain prefix that...

Datasar Platform Milestone Achievement

Today Datasar Platform successfully processed more than 2,00,000 payloads. Datasar is a flagship IoT Platform developed by Kangiten Technologies Pvt. Ltd. we have achieved one of an important milestone and many more to come.

Waste Composter Service Engg App

Waste Composter SIoT Commissioning

Waste Composter SIoT Introduction

Genset SIoT Commissioning

Genset SIoT Customer Mobile App

Genset SIoT Service Ticket Workflow

Genset SIoT & RMon Introduction

Industry 4.0

First came steam and the first machines that mechanized some of the work our ancestors did. Next was electricity, the assembly line and the birth of mass production. The third era of industry came about with the advent of computers and the beginnings of...

Manufacturing 4.0

A Road Map for IT/OT Convergence and Data-Driven Decision Making

Manufacturing 4.0 is all about “smart factories,” where machines are augmented with web connectivity and tied into a system that can visualize the entire production and chain and make decisions on its own. The trend is toward automation and data exchange in manufacturing technologies, which include cyber-physical systems (CPS), the Internet of Things (IoT), cloud computing and cognitive computing. A major component of an autonomous supply chain.